NOMURA Co.,Ltd. and Nohara Group announce the results of a demonstration of interiors pre-cut construction method using BIM*1

Delight and Passion space creation NOMURA Co.,Ltd. Co., Ltd. (Head Office: Minato-ku, Tokyo, Representative Director: Kiyotaka Okumoto, hereinafter referred to as "NOMURA Co.,Ltd.") and BuildApp® *2 Nohara Group Co., Ltd. (Head Office: Shinjuku-ku, Tokyo, Representative Director: Kosuke Nohara, hereinafter referred to as the "Nohara Group"), which is working on construction DX, continues to take on the challenge of DX centered on BIM in order to accelerate the resolution of issues in the display industry, such as a shortage of craftsmen, waste materials in interiors construction, and the lack of CO2 reduction methods.

With the cooperation of construction supply chain stakeholders such as building materials manufacturers and specialized construction companies, the two companies collaborated to conduct a comparative experiment between the pre-cut construction method *3 and conventional construction methods for major building materials for walls, floors, and ceilings in interiors construction at the Nomura Training Center (2-1-8 Shinkiba, Koto-ku, Tokyo) from January to February 2023.

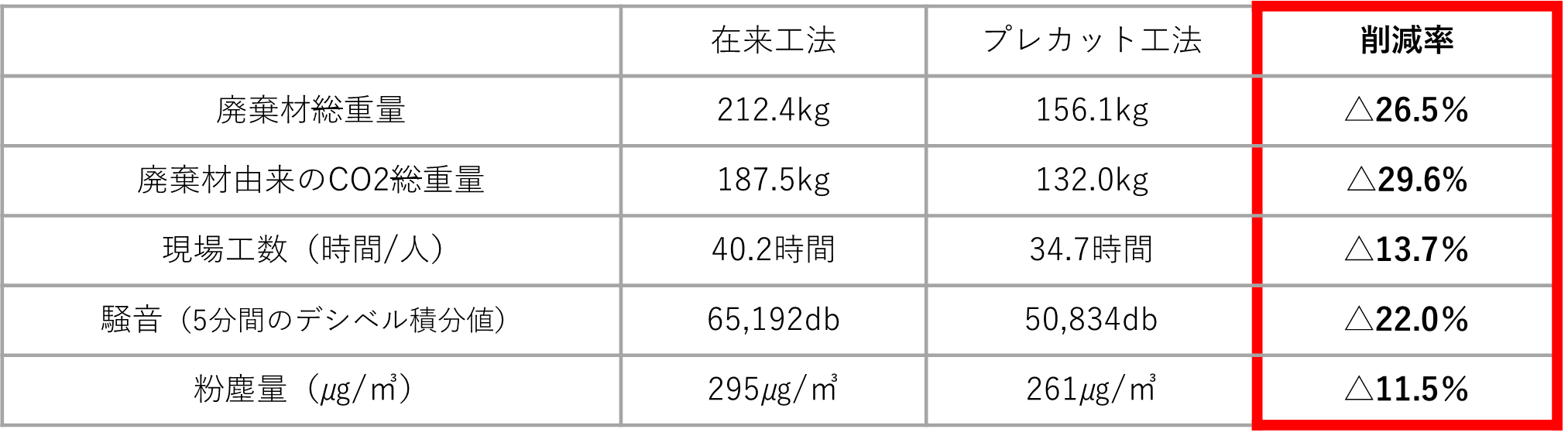

In this demonstration, the construction using the pre-cut construction method using the Nohara Group's "BuildApp" technical service resulted in a 26.5% reduction in on-site waste materials, a 29.6% reduction in CO2 emissions from waste materials, and a 13.7% reduction in on-site work time. On the other hand, it became clear that it is necessary to verify different improvement measures for each building material to improve the effectiveness of the pre-cut construction method.

NOMURA Co.,Ltd. and the Nohara Group will continue to cooperate and verify that they can contribute to the acceleration of DX in the display industry and at the same time contribute to solving issues for industry stakeholders.

*1 BIMstands for Building Information Modeling. A system that improves the efficiency of operations by having "attributes" such as floors, walls, ceilings, etc., as well as "management information" such as finishing, cost, and schedule in a three-dimensional digital model, and using the information for design, construction, and maintenance.

*2 BuildApp®replacesBIM design data created by design offices and general contractorswith more detailed data. This is a cloud service of Nohara Group Co., Ltd. that utilizes data necessary for each construction process to improve productivity throughout the construction process.

*3The pre-cut method is a method that uses materials processed in a factory in advance. In conventional construction methods, it is often processed on site.

■Demonstration overview of the interiors pre-cut method using BIM

1. Background

Traditionally, construction has relied on the skills of experienced artisans. Currently, the impact of the declining birthrate and aging population and the lack of successors due to the image of the work environment that is said to be 3K (harsh, dirty, and dangerous) have become one of the issues in the industry. DX is expected to be effective in compensating for labor shortages, but the reality is that it is later introduced than agriculture because it is difficult to see the benefits of its introduction.

We believe that visualization of issues is important to accelerate the resolution of problems through DX, so we have decided to conduct a demonstration experiment on the theme of how much on-site man-hours and CO2 can be reduced (reduction of waste materials, improvement of recycling rate) through DX throughout the supply chain (SCM) using a pre-cut construction method that utilizes BIM data, which is a digital technology.

2. Purpose of implementation

(1) Comparative verification and numerical visualization of the following items of the pre-cut construction method and the conventional construction method for walls, floors, and ceilings

・Amount of materials discarded on site

・CO2 emissions from on-site waste materials

・On-site work hours (on-site man-hours)

(2) Identification of issues for the implementation of the pre-cut method

3. Implementation details

.png)

4. Demonstration results

5. Summary and future prospects

Although a certain level of reduction in labor hours and CO2 emissions was achieved, differences in the extent of the effect were observed depending on the building material. To further improve the effect, it is necessary to verify improvement measures appropriate for each building material.

NOMURA Co.,Ltd. and the Nohara Group will continue to conduct further testing and establish the interiors pre-cut construction method using BIM as a digital transformation service for the display industry.

*4Nomura Training Centeris a platform where NOMURA Co.,Ltd. Group and partner companies come together to collaborate and create human resources who can contribute to solving customer problems and creating new value.2016Opened in .

<Partner companies> (in alphabetical order)

Advan Group Co., Ltd. | |

Kawashima Textile Cercon Co., Ltd. | |

Kanpo Steel Co., Ltd. | |

Japan Kenzai Co., Ltd. | |

Takachiho Products Co., Ltd. |

|

Tanax Co., Ltd. |

|

Tori Co., Ltd. | |

Nissho Interlife Co., Ltd. Specialized Construction Department | |

Bunso Co., Ltd. Tokyo Office | |

Meiko Densetsu Co., Ltd. |

|

Yamako Co., Ltd. | |

Yoshino Gypsum Co., Ltd. |

Please contact us using the button below if you have an inquiry, want to request a quote or request documents.

We have created a separate “FAQ page” that lists the most common questions we are asked.

Please take a look at this page if you have a question.